What can you do when coral reefs are dying because of global warming, ocean acidification, coral bleaching, pollution, and overfishing? If you’re professor Ezri Tarazi, you use new technology to create artificial reefs, which can hopefully attract fish and repopulate reefs in formerly barren areas. The twist? As chair of both the Design-Tech Lab and the industrial design program of The Technion in Haifa, Israel, he’s using 3D printing to make terra cotta tiles instead of using other materials at the Interuniversity Institute for Marine Sciences (IUI) on the shores of the Gulf of Eilat.

The lightbulb moment

“For over 30 years I’ve studied and taught industrial design,” says professor Tarazi. “In recent years, I’ve been noticing widespread mortality of fish in coral reefs, kelp forests, and rocky shores from a spike in water temperatures.

“Since 2016,” he continues, “I’ve been using 3D printing techniques for product prototypes. First, I used my printer at home to make artificial coral with bioplastic because my design team wanted to put it in the ocean to see if it became a habitable place for fish. This took about 11 hours per piece of coral.

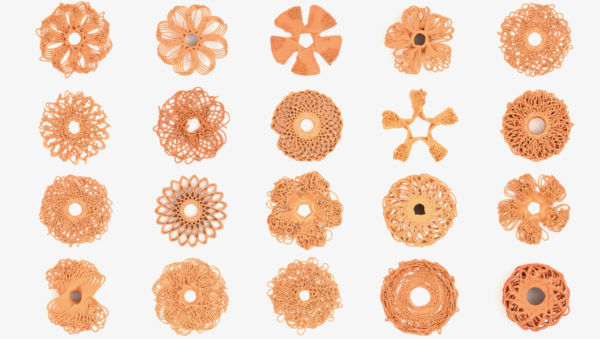

“Next, my team approached marine biologists who recommended different sizes, shapes, and colors to see which of these variations would attract particular reef fish. After three years of using the new approach of nature-centered design, which put the reef and other natural entities in the center, we used design-research tools such as observations, prototyping, user validation, and other design methods to achieve remedial interventions in nature. We then evolved to ceramics and bought a four-meter (13-foot) high 3D printer that uses clay to create ceramics from terra cotta. It prints in about 15 minutes with almost endless variations in design of lattice structures.”

What is terra cotta?

Terra cotta (baked earth) is a clay-based, kiln-fired, porous earthenware that global cultures have used dating back to 24,000 BCE. This type of coarse, porous clay material was popular with the Roman Empire, which is why Professor Tarazi and his fellow divers frequently found ceramic artifacts 2,000 years old in the shallow waters of the Red Sea.

Building artificial coral reefs

Most of the artificial reefs the team is building are about 10 feet (3 m) high by 3 feet (1 m) across. They are constructed to attract different types of fish species with different colors of coral, made from 100 percent terra-cotta material.

“Different fish are, indeed, attracted to different colors,” says Tarazi. “And each piece of coral is custom-made, burnt in a Nobertherm 210 E. kiln at 1,600 F (871.1 C), and completely unique –– like terra cotta snowflakes.

It is attractive to planula, the free-swimming, flattened, ciliated, and bilaterally symmetric larval forms of various coral species, which is helping to accelerate the growth of a natural coral reef.”

Placing the new coral

The coral is anchored to the ocean floor in the Gulf of Aqaba, south of Eilat in southern Israel in shallow waters about 4 feet (12 m) deep. From there, the shore drops off to a depth of about 333 feet (1,000 m). The circulation of the deeper, colder waters keeps the temperatures between 72 to 75 F (22 to 24 C).

Nearly 50 species of fish are now hiding, laying eggs, and sleeping in the world’s first 3D-printed bioplastics and ceramic reef in the Red Sea. These manmade reefs could be the key to rebuilding our ocean’s dying coral reefs.

The future of the project

“When we started this project, there was some hesitation in the scientific community on whether or not we should interfere with nature,” says professor Tarazi. “We are now at a point that we understand that if we don’t help nature to support itself, it would be a global disaster for all the coral reefs.

“Though this only a very narrow strip around land and islands, the Red Sea holds 25 percent of the world’s ocean biodiversity. Once you lose it, in 10 to 20 years, 90 percent of the corals may disappear. That’s why, in five to 10 years, I would love if we could shift from research to actual opportunities to install 3D-printed coral colonies, such as a whole 3D-printed reef garden, for both divers and fish.

The project’s cost

The 3D printer cost was approximately $50,000 U.S. ($42,500 Euros) and the total cost of the project is about $100,000 USD ($85,000 Euros) to date to fund the team’s research, make ceramics, purchase dive boats, and other costs.

Private donations cover some of their costs, but they would love to create strategic alliances with scuba research companies, non-profits, and other collaborations.

About Professor Ezri Tarazi

Prof. Tarazi is a full professor at the Technion, chair of t-Hub, innovation and entrepreneurship center, chair of Design-Tech Lab, and chair of the industrial design program. He is a former chair and founder of the master’s program in industrial design (M.Des) at Bezalel Academy of Art and Design in Jerusalem. He was been consulting for the Israeli government on innovation programs in the industry for almost 20 years, and member of the High Education of Israel (2006-2016).

Author Gil Zeimer took a scuba resort course on Grand Cayman in 1981. He’s been hooked ever since and has explored the underwater world from Australia to Micronesia to Aruba, almost exclusively in warm waters. As a travel writer, journalist, and advertising writer, Gil is passionate about helping diving industry clients promote their sites, resorts, and causes. He lives in Tiburon, California, which is Spanish for “shark.” Find out more about him here or follow him on Facebook.